Mumhepo inotonhorera inotonhorera zvikamu, iyodefrost kudziyisa machubhu(kana defrost heaters) ndiwo mativi epakati anovimbisa kushanda kwakanaka kweiyo firiji system. Vanogadzirisa zvakananga kukanganisa kwekuita kunokonzerwa nekuunganidza kwechando pane evaporator. Iyo nzira yekushanda kwavo uye kukosha kwekushandisa kwavo kunogona kupfupikiswa nenzira inotevera:

Ⅰ. Basa Rakakosha: Kumanikidzwa Defrosting Kuve nechokwadi cheFiriji Kushanda

1. Bvisa Frost Blockage

*** Chikonzero Chinokonzera Dambudziko: Kana air conditioner/air-cooler unit iri kushanda, tembiricha yepamusoro yezvimbi evaporator iri pasi pe0°C. Mupfunga wemvura uri mumhepo uchaita chando uye wokora zvishoma nezvishoma (kunyanya munzvimbo dzine hunyoro hunopfuura 70%).

*** Migumisiro:

~ Iyo chando inovhara zvimbi inotadzisa kuyerera kwemhepo → Huwandu hwemhepo hunoderera ne30% kusvika 50%.

~ Frost layer inoumba dhizaini inodzivirira kupisa → Kushanda kwekutsinhanisa kupisa kunodonha nekupfuura 60%.

~ Iyo compressor inomanikidzwa kushanda kwenguva yakareba nekuda kwekuderera kwekudzoka gasi kudzvanywa → simba rekushandisa rinowedzera.

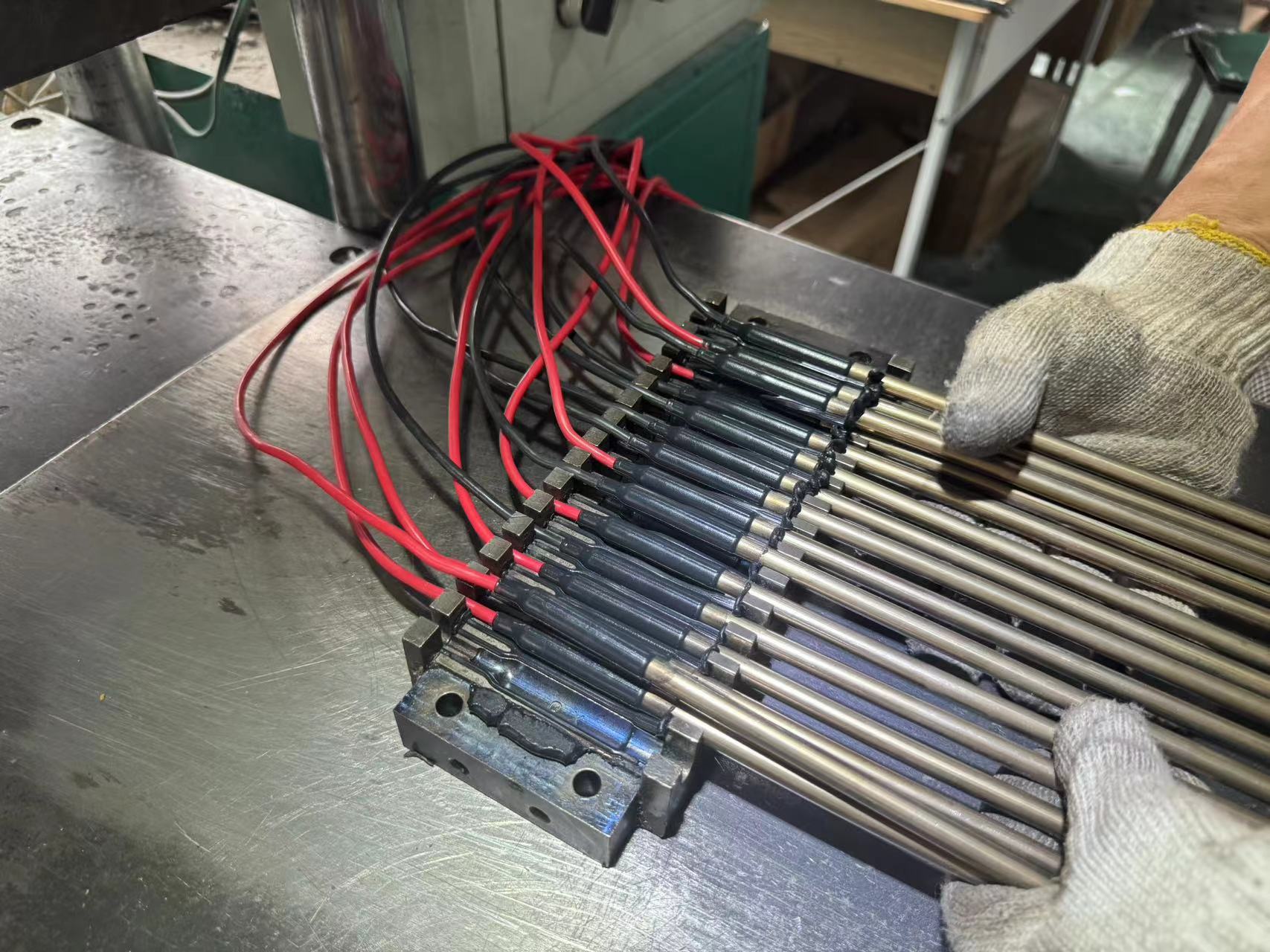

*** Heating tube solution:

Mushure mekushandisa simba, pamusoro peiyodefrost heat tubeinokwira kusvika 70 - 120 ℃, ichinyungudusa chando chechando pakati pezvimbi → kudzoreredza nzira yemhepo uye nekunatsiridza kupisa kwekupisa.

2. Kudzivirira kuvharwa kweaizi muhurongwa hwemvura

*** Pfungwa huru yekurwadza: Kana pombi yemvura iri pazasi pefeni yekutonhodza ikaita chando uye yakavharika, mvura inopedza chando inoyerera ichidzokera muimba yekuchengetera zvinhu yogwamba, zvichikonzera njodzi.

*** Heating tube application:

Putira silicone rabha yekudonhedza tambo yekudziya waya yakatenderedza pombi yemvura (ine simba rehuwandu hwe40-50W/m), uchichengetedza tembiricha yepombi iri pamusoro pe5℃ → Ita shuwa kuti mvura inobvisa chando inogona kubuda zvakanaka.

Ⅱ. Basa Logic uye System Kubatana

1. Defrosting Trigger Mechanism

*** Kudzora Nguva: Tanga kudzikisira zvinoenderana neyakagadzikwa kutenderera (semuenzaniso, defrost kamwe chete maawa matanhatu);

*** Kunzwa tembiricha: Tembiricha yepasi sensor ye evaporator inoona ukobvu hwechando. Kana pachikumbaridzo chasvika, defrosting inokonzerwa.

*** Kudzvanya mutsauko wekudzora: Tarisa musiyano wekumanikidza pakati pemativi maviri eevaporator. Kana mutsauko wakapfuura muganhu, zvinoratidza kuti kupikisa kwemhepo kwakanyanyisa uye kusvibiswa kunodiwa.

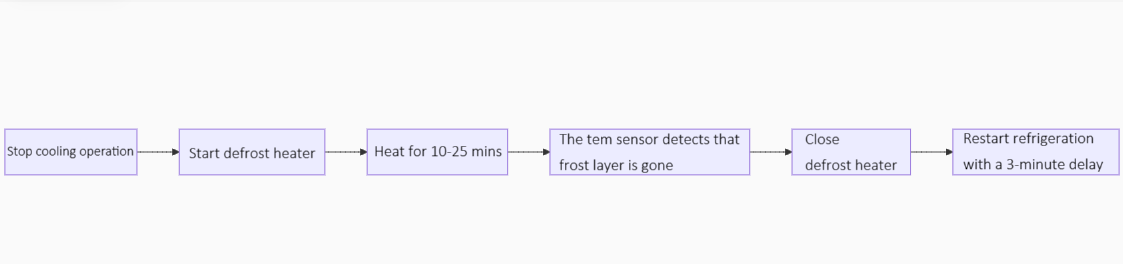

2. Defrosting Procedure

Ⅲ. Dhizaini Zvimiro uye Kuenderana neCold Storage

| Hunhu | Zvinodikanwa zveCold Storage Application | Defrost Heating Tube Implementation Scheme |

| Low Temperature Flexibility | Zvichiri kudikanwa kunamatira zvakanyanya kune zvimbi pane tembiricha iri pasi -30 ℃ | Yakapfava silicone yekunze layer inochengetedza kuchinjika, hapana njodzi yekuputsika panguva yekuisa mhepo |

| Kuvharirwa kwemvura kusingapindi | Yakakwira humidity nharaunda (hunyoro hunyoro mune inotonhora yekuchengetedza> 90%) | Kaviri-layer silicone insulation + majoini akaumbwa, chiyero chisina mvura pamusoro peIP67 |

| Precise Temperature Control | Inodzivirira kupisa kukuvadza kune fin aluminium zvinhu | Yemukati tembiricha fuse (kunyungudika 130 ℃) kana yekunze tembiricha controller |

| Corrosion Resistance | Kudzivirira kudzikisa mvura uye refrigerant nharaunda | Fluorine-yakavharwa kana 316 simbi isina tsvina sheath modhi (yemakemikari inotonhorera yekuchengetedza) |

Ⅳ. Yakananga Benefits uye Isina Kunanga Kukosha

1.Energy Kuchengetedza uye Kuderedza Mutengo

*** Kubvisa chando nenguva kunodzoreredza kushanda kwefiriji kusvika pamusoro pe95%, kunopfupisa nguva yekushanda kompressor → Kushandiswa kwesimba kwese kunoderedzwa ne15% kusvika 25%.

*** Nyaya: Kana firiji -18 ℃ ikatadza kubvisa chando nenguva, kushandiswa kwemagetsi pamwedzi kwakawedzera ne8,000 mayunitsi. Mushure mekuisa machubhu ekudziya, yakadzokera kune yakajairika.

2. Iva nechokwadi chekuchengetedzwa kwezvinhu

*** Kuchinjana kwakanaka kwekupisa kweevaporator → Kuchinja kwehutambiricha munzvimbo yekuchengetera kuri mukati ±1℃ → Dzivirira zvigadzirwa zvakaomeswa nechando kuti zvisanyunguduke nekuipa kana kukuvadza chimiro chesero nemakristasi echando.

3. Wedzera hupenyu hwemidziyo

*** Kuderedza kazhinji kutanga-kumira uye yakakwirira-mutoro kushanda kwecompressor → Hupenyu hwezvinhu zvakakosha zvinogona kuwedzerwa ne3 kusvika kumakore mashanu;

*** Kudzivirira kuparuka kweaizi mumapombi anofambisa mvura → Kuderedza njodzi yekudonha kwefiriji.

Ⅴ. Kusarudza uye Kugadzirisa Mazano Akakosha

1. Simba density kuenzanisa

*** Mhepo inotonhorera isingaremi: 30 - 40W pamamita (ine gap pakati pezvimbi> 5mm);

*** Inorema-basa reindasitiri mhepo inotonhorera: 45 - 60W pamamita (yakanyanya kupisa kupinda inodiwa kune dense fins).

2. Kuiswa Zvinyorwa

*** Machubhu ekudziisa hita anofanira kugovaniswa zvakaenzana pakati pezvimbi, nepakati isingadarike masendimita gumi (kudzivirira chero nzvimbo dzisave nechando chakanyunguduka).

*** Iyo inotonhora yekupedzisira waya inofanira kuchengetwa neinosvika masendimita makumi maviri, uye mapoinzi ekubatanidza anofanirwa kuvharwa neakadzika-tembiricha asingachinji silicone gel.

3. Kudzivirira Mhosva

*** Gara uchiyedza iyo insulation kuramba (> 200MΩ) kudzivirira kuvuza.

*** Chenesa zvimbi zveguruva gore rega rega kudzivirira kuunganidzwa kweguruva, izvo zvinoderedza kupisa kwekufambisa kushanda.

Iyo firiji defrost heater inopisa chinhu inoita basa re "system muchengeti" mumhepo inotonhora yekuchengetera inotonhora:

Panyama: Inotyora kukiya echando, inodzoreredza chiteshi chekuchinjana kupisa;

Economically: Kuburikidza nekuchengetedza simba nekudzivirira kukanganisa, kunoderedza zvakanyanya mari yekushandisa;

Tekinoroji: Iko kusanganiswa kwesilicone zvinhu uye nehungwaru tembiricha yekudzora inovimbisa yakachengeteka uye chaiyo de-icing maitiro.

Pasina iyo defrost yekudziya chubhu, inotonhora mhepo inofefetera yakafanana neinjini yakaomeswa nechando panzvimbo - inoita seiri kushanda, asi iine zero inoshanda.

Nguva yekutumira: Jul-11-2025