Iyo defrost heater element ndechimwe chezvinhu zvakakosha zvakakosha mumafiriji nemafiriza. Basa rayo guru nderokudzivirira kuumbwa kwechando nekunyungudutsa ice layer yakaunganidzwa pamakoiri evaporator. Dhizaini ye defrost heater chubhu yakakosha kuchengetedza kushanda kwakajairwa kwemidziyo. Kunyanya, kana mweya uri mukati mefiriji kana mufiriji uchipfuura nemuevaporator yekutonhodza, hunyoro hwemhepo hunogona kudzika uye zvishoma nezvishoma kutonhora pamusoro peiyo evaporator. Kana aya mazaya echando akasabviswa nekufamba kwenguva, anozokora zvishoma nezvishoma uye anokanganisa kutenderera kunoshanda kwemhepo inotonhora, zvichikanganisa kufanana uye kugadzikana kwekushisa kwemukati kwemidziyo.

Kuve nechokwadi chekuti mafiriji kana mafiriza anogona kuramba achipa inogara yakadzika-tembiricha nharaunda, vagadziri vanowanzoisa otomatiki defrosting system mumidziyo. Chinhu chakakosha cheiyi system ndeye defrost heat element, iyo inotanga panguva dzakafanotemerwa nguva uye inotamisa huwandu hwakakodzera hwekupisa kune evaporator coils kuti inyungudise aizi yakaunganidzwa. Iyi periodic defrosting operation haingobatsiri kuchengetedza kutenderera kwemhepo mukati memudziyo asi zvakare inovandudza kushanda kwefiriji uye kuderedza kushandiswa kwesimba.

Nheyo yekudzikisa mufiriji - Chii chinonzi mhepo inotonhorera firiji

Kubatsira kukuru kwemhepo inotonhorera firiji ndeyokuti haina chando. Kusiyana nemafiriji ane masisitimu efiriji, firiji inotonhodzwa nemhepo haina mukati inogara yakanyorova, uye chikafu hachinamati pamwe chete. Uyezve, firiji yakanyoroveswa nemhepo ine kutenderera kunoramba kuripo kwemhepo inotonhora, iyo inonatswa neiyo deodorization system, uye kunhuhwirira kwemukati kuchachengetwa kutsva kwenguva yakareba, pasina kusingafadzi "kunhuhwirira kwefiriji" zvakare. Firiji inotonhorera nemhepo haina chando; asi, chando chinodzika pane evaporator. Sezvo iri mukati mefiriji, hatigoni kuiona zvakananga dhoo refiriji rakavhurika, saka nenzira yokufananidzira inonzi isina chando. Pamusoro pezvo, nekuti firiji yakatonhodzwa nemhepo inogona kudzima.

Iyo defrosting musimboti wemhepo-yakatonhorera firiji - Kushanda musimboti wekusvibisa mufiriji inotonhorera

Mushure mekunge maitiro ekubvisa chando apera mukutenderera kwapfuura, iyo yekudzikisa nguva inobata grey mutsara uye mutsara weorenji wakabatana, uye timer, compressor, uye fan zvese zvinotanga kumhanya panguva imwe chete. Iyo defrosting timer yakabatanidzwa munhevedzano neiyo defrost heater, asi nekuda kwekukura kwemukati kupikisa kweiyo defrost timer uye kudiki kwemukati kushomeka kweiyo defrost heater, yakawanda yevoltage inoshandiswa kune defrost timer, uye defrost heater inogadzira kupisa kushoma. Kana iyo defrost timer uye compressor ichimhanya panguva imwe chete kwehuwandu hwemaawa masere, mabatiro eiyo defrost timer's grey mutsara uye orange line akabatana. Iyo defrost heater inofambiswa zvakananga nefuse uye defrost switch, uye iyo defrost mota ipfupi-inotenderedzwa neiyo defrost tembiricha yekudzora switch. Iyo defrost timer inomira kumhanya.

Kana chando chanyunguduka zvachose, kana tembiricha yepasi ye evaporator ichikwira kusvika 10-16 ° C, iyo defrost tembiricha yekudzora switch contacts inobviswa kubva ku defrost circuit, uye panguva imwe chete, defrost timer inotanga kushanda. Mushure memaminitsi angangoita mashanu, mabatirwo emutsara wegrey uye mutsara weorenji akabatana zvakare, achizadzisa imwe otomatiki defrosting process. Iyo compressor uye fan inotanga kumhanya zvakare kune firiji. Zvadaro, apo tembiricha ye evaporator inodonha kusvika kune reset tembiricha ye defrost tembiricha control switch, tembiricha yekudzora tembiricha yakavharwa kuti ibatanidze defrost heater, ichigadzirira iyo inotevera defrosting.

Nekudaro, kana defrost heat element ikasashanda, senge nekuda kwekuchembera, kupisa kunze, kana kusabatana kwedunhu, zvinogona kudzivirira defrost kutenderera kushanda nemazvo. Nekuda kweizvozvo, chando pane evaporator inogona kuungana nekukurumidza, ichivharira nzira yekuyerera kwemhepo uye kuita kuti zviome kumidziyo kuchengetedza tembiricha yakatarwa. Mamiriro ezvinhu aya haangokanganisa kuchengetedzwa kwechikafu chete, asiwo anokonzeresa kushushikana pazvinhu zvakakosha secompressor, uye zvinogona kutotungamira mukukuvadzwa kwemidziyo. Nokudaro, paunoona kuderera kwekushanda kwekutonhora kwefiriji yako kana firiji, kuunganidza kusina kujairika kwechando mukati, kana kuwedzera kukuru kwekushandiswa kwesimba, unofanira kukurumidza kutarisa chimiro che defrost system.

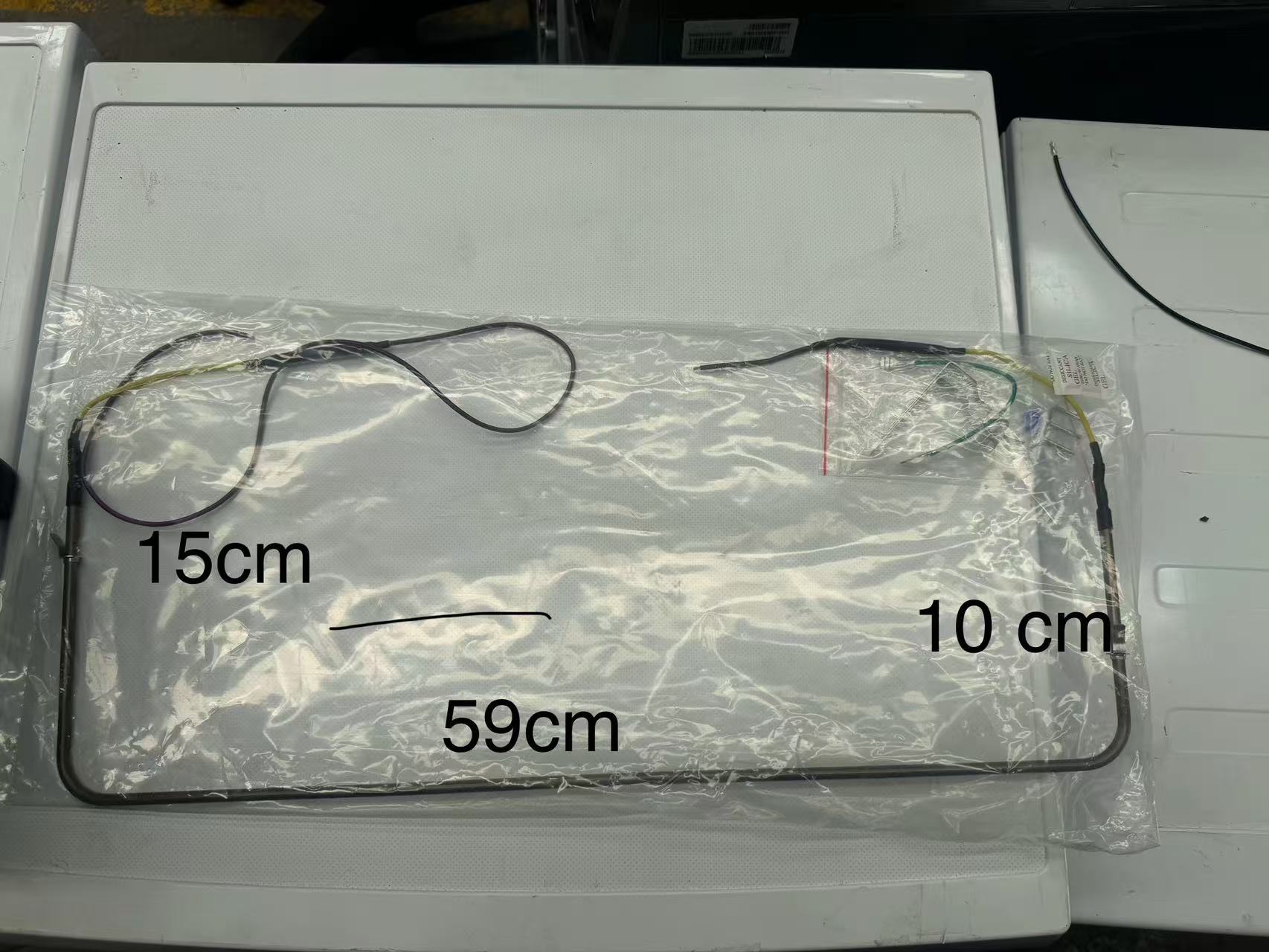

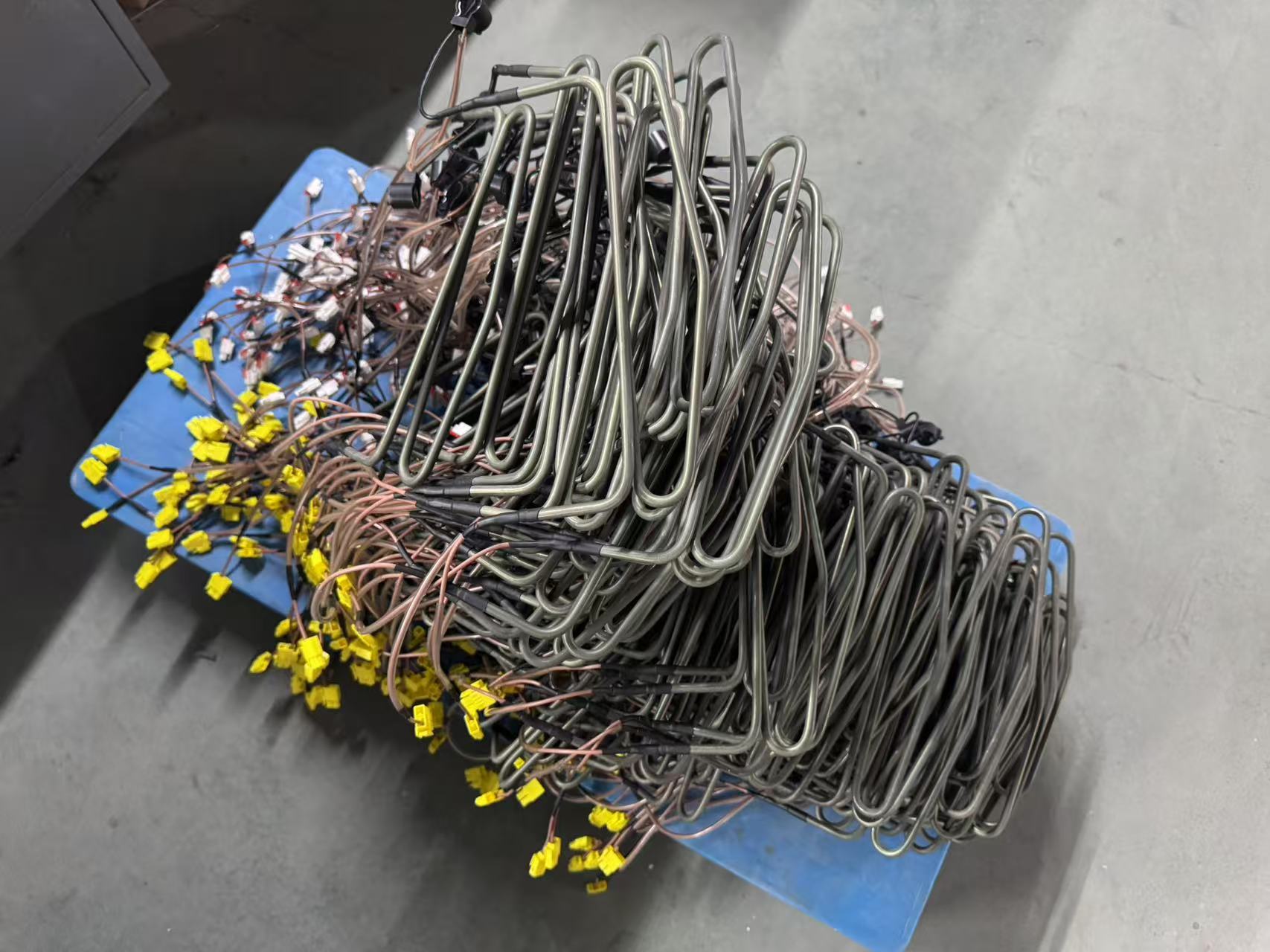

Kana iwe uchifungidzira kuti defrost heat element yakashata, zvinokurudzirwa kuti utore matanho anotevera nokukurumidza sezvinobvira: Kutanga, bvisa magetsi emagetsi ekugadzirisa kuchengetedza; chechipiri, shandisa multimeter kuti uedze kukosha kwekupikisa kwechinhu chinopisa kuti uone kana chiri mukati mehutano hwekushanda; pakupedzisira, kana zvakasimbiswa kuti chikamu chakakuvadzwa, unoda kutenga chikamu chitsva chinoenderana nemuenzaniso wepakutanga wekutsiva. Nekuchengetedza uye kutsiva zvikamu zvisina kunaka panguva yakakodzera, unogona kunyatso kuwedzera hupenyu hwesevhisi kana firiji uye kuve nechokwadi kuti inogara iri mune yakanakisa kushanda mamiriro.

Nguva yekutumira: Kubvumbi-26-2025